ASHRAE Standard 62.1-2010 Ventilation for Acceptable Indoor Air Quality

Presented by

Roger Hedrick, LEED AP, BEMP Chair, SSPC 62.1

ASHRAE Standard 62.1 Overview

General comments

General requirements

Ventilation requirements

Construction and O/M requirements

Energy Efficiency Options

Possible Coming Changes

Questions

ASHRAE Standard 62.1 What’s Its History? 62-1981 Alternative Air Quality Proc.

1970

62-1973 first issued

1980

62-1999 • IAQ-Health disclaimers • Smoking disclaimers • Clarified CO2as ventilation metric

62-2001 •Prescriptive •Commissioning •O&M •Combustion air •Filtration 62.1-2007 Updated

1990

62-1989 • Removed Thermal Comfort • Ventilation Rate Proc. • IAQ Proc.

2000

2010

62.1-2004 •Commercial and High Rise Res. •Enforceable code language •ETS vent. rates not covered •Vent. Rate. Proc. Modified •Occupant and area vent. rates

1. Purpose

1.1 Specify minimum ventilation rates and other measures intended to provide IAQ that is acceptable to human occupants and that minimizes adverse health effects

1.2 Intended for regulatory application to new buildings and additions

1.3 Guide the improvement of IAQ in existing buildings

2. Scope

2.1 All spaces intended for human occupancy excluding low-rise residential (62.2)

2.2 Defines requirements for ventilation, air-cleaning design, commissioning, installation and O&M

2.3 Additional requirements and other standards may apply (labs, healthcare, industrial, etc.)

2.4 May be applied to both new and existing buildings, not intended to be used retroactively

2.5 Does not prescribe specific ventilation rates for smoking spaces

2. Scope

2.6 Ventilation requirements based on chemical, physical, & biological contaminants 2.7 Consideration or control of thermal comfort is not included 2.8 In addition to ventilation, the standard contains requirements related to certain sources

2. Scope

2.9 Acceptable IAQ may not be achieved in all buildings meeting these requirements because of:

Diversity of sources and contaminants

Air temperature, humidity, noise, lighting, and psychological/social factors

Varied susceptibility in the occupants

Introduction of outdoor contaminants

3. Definitions

36 Terms Defined

Two of Particular Significance

Acceptable Indoor Air Quality

Occupiable Space

General Requirements 4. Outdoor Air Quality

4.1 Regional Air Quality

Must determine NAAQS attainment status www.epa.gov

Air cleaning is required in some cases in non-attainment areas

4.2 Local Air Quality

Conduct observational site survey to identify local sources of air contaminants

General Requirements 4. Outdoor Air Quality

4.3 Documentation

Regional air quality compliance status

Local survey information

Conclusions regarding acceptability of outdoor air quality

General Requirements 5. Systems and Equipment

5.1 Ventilation Air Distribution

Must provide means to adjust the system Minimum ventilation air must be provided to each terminal unit in ceiling/floor plenum systems

General Requirements 5. Systems and Equipment

5.2 Exhaust Duct Location

5.3 Ventilation System Controls

Operate exhaust ducts with harmful contaminants at negative pressure

Control to assure proper ventilation under any operating condition

5.4 Airstream Surfaces

Use materials that have documented resistance to microbial growth and erosion

General Requirements 5. Systems and Equipment

5.5 Outdoor Air Intakes

Separate OA intake from outdoor contaminant sources

Must comply with default minimum separation distances in Table 5-1. Examples:

Loading dock Dumpster Surface below intake Cooling tower exhaust

25 ft 15 ft 1 ft 25 ft

Must limit moisture penetration (using hood, proper velocity, etc.) or manage water that penetrates

Prevent moisture intrusion into equipment mounted outdoors

Must use bird screens and prevent bird nesting

General Requirements 5. Systems and Equipment

5.6 Local Capture of Contaminants

Discharge air from non-combustion equipment that captures contaminants shall be exhausted to the outdoors

5.7 Combustion Air

Follow manufacturer’s instructions to provide sufficient combustion air and exhaust air for indoor fuel-fired appliances Products of combustion from vented appliances shall be vented directly outdoors

General Requirements 5. Systems and Equipment

5.8 Particulate Matter Removal

Use a filter rated at MERV 6 (or greater) upstream of cooling coils and other wet-surface devices in supply stream

General Requirements 5. Systems and Equipment

5.9 Dehumidification Systems

Must be able to limit indoor RH to 65% or less at design dew point condition

Exception to RH limit - where occupancy requirements or processes dictate higher RH conditions

Intake airflow must be greater than relief/exhaust during cooling (to minimize moist air infiltration)

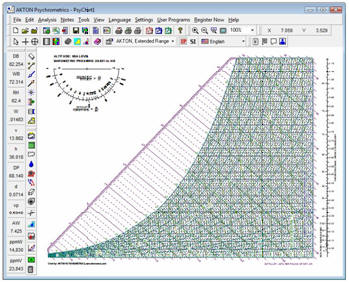

General Requirements 5.9 Dehumidification Systems 65% RH limit

62°F DP

General Requirements 5. Systems and Equipment

5.10 Drain Pans

Assure drainage without flooding or carryover Slope: 0.125” (1/8”) per foot toward outlet Drain: located at lowest point, with sufficient diameter prevent overflow Drain seal: Shall include P-trap or other seal for negatively pressurized drain pans to prevent ingestion of air while allowing complete drainage (fan on or off) Pan size: length at least 1/2 coil height or as necessary to limit carryover

General Requirements 5. Systems and Equipment

5.11 Finned Tube Coils and Heat Exchangers

Provide drain pan beneath all dehumidifying cooling coil assemblies and all condensate producing heat exchangers Select to limit coil pressure drop to 0.75 [email protected] 500 fpm face velocity

Exception- higher pressure drop can be accommodated by providing access on both sides and providing clear and complete instructions for maintenance

General Requirements 5. Systems and Equipment

5.12 Humidifiers and Water Spray Systems

Use potable water (or better) No downstream devices within absorption distance

Exception- devices or obstructions provided with appropriate drain pan

General Requirements 5. Systems and Equipment

5.13 Access for Inspection, Cleaning and Maintenance.

Install equipment with sufficient working space for access and maintenance Provide access doors, panels or other means to allow convenient and unobstructed access for maintenance of the HVAC system

General Requirements 5. Systems and Equipment

5.14 Building Envelope and Interior Surfaces

Weather barrier to prevent water penetration into envelope

Vapor retarder or other means to prevent condensation on cold surfaces within envelope

Seal all exterior seams, joints, penetrations to limit infiltration

Insulate pipes and ducts expected to have surface temperature below surrounding dew point

General Requirements 5. Systems and Equipment

5.15 Buildings with Attached Parking Garages.

Limit infiltration of vehicular exhaust:

Maintain garage pressure at or below adjacent occupied space Or, use a vestibule Or, otherwise design to minimize air migration from garage to occupied space

General Requirements 5. Systems and Equipment

5.16 Air Classification and Recirculation.

Designate expected air quality classification for all return transfer or exhaust air (refer to table 5.2, 6.1 and 6.4 for examples of air classes)

Class 1: Low contaminant concentration

Class 2: Moderate concentration

Class 3: Significant concentration

Class 4: Highly objectionable or potentially harmful concentration

General Requirements 5. Systems and Equipment

Recirculation limitations

Class 1 to anywhere Class 2 to self, similar Class 2 or Class 3 or Class 4

Class 3 to self

Class 4 to outdoors

General Requirements 5. Systems and Equipment

Re-designation of air class

Air Cleaning- may allow re-designation of the air to a cleaner classification. Transfer- a mixture of air with different classes shall be re-designated with the highest class of classification among the air classes mixed. Energy Recover- energy recovery from class 2 (exhaust) airstreams must have no more than 10% leakage into a class 1 airstream.

General Requirements 5. Systems and Equipment

5.17 Requirements for buildings containing ETS areas and ETS-Free areas.

Note - Does not purport to achieve acceptable IAQ in ETS areas.

Spaces must be classified as ETS or ETSFree

ETS-Free areas shall be at a positive pressure in relation to ETS areas

General Requirements 5. Systems and Equipment

5.17 (continued)

ETS-Free areas must be kept separate by means of solid walls, floors, ceilings and doors with automatic closers. Recirculation or transfer from ETS to ETS-Free is prohibited ETS areas must be exhausted to prevent recirculation to ETS-Free areas

Ventilation Requirements 6. Procedures

6.1 General- Three different procedures are available to determine the outdoor airflow rates for mechanical ventilation systems.

Ventilation Rate Procedure- Prescribes rates & procedures based on typical space contaminant sources & source strengths

Ventilation Requirements 6. Procedures

IAQ Procedure- Requires calculation of rates based on analysis of contaminate sources, concentrations and perceived air quality targets Natural Ventilation Rate ProcedurePrescribes design criteria for ventilation air to be provided through openings to the outdoors

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.1 Outdoor Air Treatment. If outdoor air is judged to be unacceptable per Section 4.1 assessment

MERV 6 filter in PM10 non-attainment regions

MERV 11 filter in PM2.5 non-attainment regions

40% efficient ozone filter in some ozone nonattainment regions

Other – document assumptions

Air Data: PM10

Air Data: Ozone Above 160 ppb: Fresno, Riverside, Long Beach

Ventilation requirements 6.2 Ventilation Rate Procedure

6.2.2 Zone Calculations.

Use Table 6.1 rates (both cfm/person and cfm/sf) to find breathing zone outdoor airflow: Vbz = Rp*Pz + Ra*Az

GENERAL NOTES FOR TABLE 6-1

1 Related requirements: The rates in this table are based on all other applicable requirements of this standard being met. 2 Smoking: This table applies to nosmoking areas… 4 Default occupant density: The default occupant density shall be used when actual occupant density is not known.

Ventilation Rate Procedure Minimum Ventilation Rates

Table 6-1: Minimum breathing-zone rates for 78 categories Std 62-2001

Std 62.1-2010

Rp cfm/p

Ra cfm/ft²

Rp cfm/p

Ra cfm/ft²

Office

20

0.0

5.0

0.06

Classroom (ages 5-8)

15

0.0

10.0

0.12

Lecture classroom

15

0.0

7.5

0.06

Retail sales

0

0.3

7.5

0.12

Auditorium

15

0.0

5.0

0.06

Occupancy category

Prescribes both per-person and per-area rates

Ventilation Rate Procedure Minimum Ventilation Rates Comparison of breathing-zone OA flow Std 62-2001

Std 62.1-2010

Occupancy category (default density/1000 ft²)

Vbz cfm

Effective cfm/p

Vbz cfm

Office

100

20.0

85

17.0

Classroom (ages 5-8) (25p)

375

15.0

370

15.0

Lecture classroom

(65p)

975

15.0

550

8.5

Retail sales

(15p)

300

20.0

233

16.0

Auditorium

(150p)

2250

15.0

810

5.4

(5p)

Effective cfm/p

Most OA flow rates go down a little … some, a lot!

Zone Outdoor Airflow

Use Table 6.2 defaults to find zone air distribution effectiveness, Ez Find zone outdoor airflow for each zone: Voz = Vbz/Ez

Ez can range from 0.5 to 1.2 Ez=0.8 with certain common heating designs. This is 25% more OA.

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.3 Single-Zone Systems. Find system-level outdoor air intake flow: Vot = Voz

6.2.4 100% Outdoor Air Systems. Find system-level outdoor air intake flow: Vot = Σ Voz

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.5 Multiple-Zone Recirculating Systems. Use prescribed equations to find outdoor air intake flow (Vot):

[

1 × D ∑allzones R p Pz + ∑allzones Ra Az Vot = Ev

]

Spreadsheets

There is a spreadsheet supplied with the Users manual that aids in calculating Vot, the air required at the outdoor air intake.

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.6 Design for Varying Operating Conditions.

Must provide required ventilation rates whenever occupied

May (optional) base design calculations on averages over three time-constants: T = 3 ν / Vbz

(IP units)

Average zone population (Pz) when population varies

Average breathing zone outdoor airflow (Vbz) when primary airflow varies

Average outdoor air intake flow (Vot) when intake flow varies

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.7 Dynamic Reset

May (optional) reset intake (Vot) or zone minimum airflow based on variations in estimated occupancy, efficiency, or actual intake airflow

Ventilation Requirements 6.3 IAQ Procedure

Performance-based design approach Designed to maintain the concentrations of specific contaminants and Achieve the design target level of perceived indoor air quality acceptability

Ventilation Requirements 6.3 IAQ Procedure (cont)

Allows contaminant removal through air cleaning in addition to ventilation

Allows tailoring ventilation rate to specifics of the space

May allow ventilation rates to be reduced below levels prescribed by the Ventilation Rate Procedure. IAQ Procedure requirements are being made more specific

Ventilation Requirements 6.3 IAQ Procedure

Designing for compliance using the IAQ Procedure requires four steps:

Identify contaminants of concern, along with sources and emission rates

Specify target concentration and exposure time

Specify target perceived air quality in terms of percent satisfied

Follow an acceptable design procedure to find required airflow values.

Ventilation requirements 6.3.4 IAQ Procedure

Rate is larger of that determined by

Mass balance analysis, AND

Subjective Evaluation, OR

Design approaches that have proved successful in similar buildings

Can combine VRP and IAQP

Ventilation Requirements 6.3.4.1 IAQ Procedure (cont)

Mass balance analysis equations are provided in Appendix D Equations are limited to the steady-state analysis of a single zone Not specified by the Standard, but use simulation software for multiple zone systems

Ventilation Requirements 6.3 IAQ Procedure

May be used:

To take credit for low-emitting materials

To take credit for air cleaning

To achieve specific target concentrations of one or more contaminants

To achieve specific levels of perceived IAQ (percent satisfied)

Does not apply for ETS … no acceptable concentration to reference

Ventilation Requirements 6.4 Natural Ventilation

Requires occupant controllable openings to outdoors Minimum size of openings based on floor area to be ventilated Requires mechanical ventilation system be installed – VRP or IAQP

Ventilation Requirements 6.4 Natural Ventilation

Floor area that can be naturally ventilated based on multiple of ceiling height Multiplier based on opening configuration

One-sided – 2h

Two-sided – 5h

Corner – 5h along line

Ventilation Requirements 6.5 Exhaust Ventilation

Must provide exhaust for some space types Rates prescribed in Table 6.4. For instance:

Kitchenettes

0.30 cfm/ft2

Public toilet

50 cfm/unit (typ)

Art classroom

0.70 cfm/ft2

Construction Requirements 7. Construction/Start-Up

7.1 Construction Phase

Don’t operate air handlers without filters

Protect building materials

Protect occupied areas

Limit migration of construction contamination into occupied space

Construction Requirements 7. Construction/Start-Up

Air Duct System Construction shall be in accordance with the SMACNA duct construction standards and NFPA standards governing installation of HVAC systems 7.2 System Start-Up- Defines the testing or inspecting for cleanliness, functional operation and balancing of the HVAC system

Construction Requirements 7. Construction/Start-Up

Documents shall be provided to Owner including:

Balancing report,

As-built construction drawings, and

Design criteria with assumptions

Operating Requirements 8. Operation & Maintenance

8.2 Operations and Maintenance Manual.

Develop a building operations and maintenance manual which shall include a maintenance schedule with frequencies of tasks. O&M manual shall be provided to Owner of the building

Operating Requirements 8. Operation & Maintenance

8.3 Ventilation System OperationOperate in accordance with Building O&M Manual and Section 6 when spaces are expected to be occupied. 8.4 Ventilation System MaintenanceMaintain in accordance with Building O&M Manual or as required by Section 8.

Saving Energy

Careful design

Maximize effectiveness and efficiency

Vary operation as conditions change

Use time averaging when appropriate

Saving Energy

DOAS

Separates ventilation from temperature control Allows optimizing ventilation

Natural ventilation

Must control mechanical system properly!

Saving Energy

IAQ Procedure

Most appropriate for multiple similar buildings

Known contaminants that can be cleaned

Designer/Owner must accept liability

Not LEED!

SSPC 62.1

Standard is under continuous maintenance

Anyone can propose a change to the standard

Notice of proposed changes appears in ASHRAE Standards Action

Anyone can comment on proposed changes

Anyone can request an interpretation

ASHRAE Standard 62.1-2010 & Related Activities…

Std 62.1-2010 is the current version IMC & UMC adopted equations and ventilation rates Several educational courses are available from ASHRAE

ASHRAE 62.1 Resources

User’s Manual for 62.1-2010

IMC & UMC Code adoption

ALI Short Course and Professional Development Course

eLearning course

IAQ Design Guideline is published

Next publication – ASHRAE 62.1-2013

ASHRAE 62.1 Future Changes

Complete ventilation shutoff when zero occupancy

More specifics for multizone DCV

More refinement for space types

Better integration for VRP and Exhaust

More space types?

ASHRAE 62.1 Future Changes

IAQP

More design guidance

More rigor

Code/LEED acceptance?

General improvements

Code integration

Questions? Roger Hedrick [email protected] 303 459 7481

Presented by

Roger Hedrick, LEED AP, BEMP Chair, SSPC 62.1

ASHRAE Standard 62.1 Overview

General comments

General requirements

Ventilation requirements

Construction and O/M requirements

Energy Efficiency Options

Possible Coming Changes

Questions

ASHRAE Standard 62.1 What’s Its History? 62-1981 Alternative Air Quality Proc.

1970

62-1973 first issued

1980

62-1999 • IAQ-Health disclaimers • Smoking disclaimers • Clarified CO2as ventilation metric

62-2001 •Prescriptive •Commissioning •O&M •Combustion air •Filtration 62.1-2007 Updated

1990

62-1989 • Removed Thermal Comfort • Ventilation Rate Proc. • IAQ Proc.

2000

2010

62.1-2004 •Commercial and High Rise Res. •Enforceable code language •ETS vent. rates not covered •Vent. Rate. Proc. Modified •Occupant and area vent. rates

1. Purpose

1.1 Specify minimum ventilation rates and other measures intended to provide IAQ that is acceptable to human occupants and that minimizes adverse health effects

1.2 Intended for regulatory application to new buildings and additions

1.3 Guide the improvement of IAQ in existing buildings

2. Scope

2.1 All spaces intended for human occupancy excluding low-rise residential (62.2)

2.2 Defines requirements for ventilation, air-cleaning design, commissioning, installation and O&M

2.3 Additional requirements and other standards may apply (labs, healthcare, industrial, etc.)

2.4 May be applied to both new and existing buildings, not intended to be used retroactively

2.5 Does not prescribe specific ventilation rates for smoking spaces

2. Scope

2.6 Ventilation requirements based on chemical, physical, & biological contaminants 2.7 Consideration or control of thermal comfort is not included 2.8 In addition to ventilation, the standard contains requirements related to certain sources

2. Scope

2.9 Acceptable IAQ may not be achieved in all buildings meeting these requirements because of:

Diversity of sources and contaminants

Air temperature, humidity, noise, lighting, and psychological/social factors

Varied susceptibility in the occupants

Introduction of outdoor contaminants

3. Definitions

36 Terms Defined

Two of Particular Significance

Acceptable Indoor Air Quality

Occupiable Space

General Requirements 4. Outdoor Air Quality

4.1 Regional Air Quality

Must determine NAAQS attainment status www.epa.gov

Air cleaning is required in some cases in non-attainment areas

4.2 Local Air Quality

Conduct observational site survey to identify local sources of air contaminants

General Requirements 4. Outdoor Air Quality

4.3 Documentation

Regional air quality compliance status

Local survey information

Conclusions regarding acceptability of outdoor air quality

General Requirements 5. Systems and Equipment

5.1 Ventilation Air Distribution

Must provide means to adjust the system Minimum ventilation air must be provided to each terminal unit in ceiling/floor plenum systems

General Requirements 5. Systems and Equipment

5.2 Exhaust Duct Location

5.3 Ventilation System Controls

Operate exhaust ducts with harmful contaminants at negative pressure

Control to assure proper ventilation under any operating condition

5.4 Airstream Surfaces

Use materials that have documented resistance to microbial growth and erosion

General Requirements 5. Systems and Equipment

5.5 Outdoor Air Intakes

Separate OA intake from outdoor contaminant sources

Must comply with default minimum separation distances in Table 5-1. Examples:

Loading dock Dumpster Surface below intake Cooling tower exhaust

25 ft 15 ft 1 ft 25 ft

Must limit moisture penetration (using hood, proper velocity, etc.) or manage water that penetrates

Prevent moisture intrusion into equipment mounted outdoors

Must use bird screens and prevent bird nesting

General Requirements 5. Systems and Equipment

5.6 Local Capture of Contaminants

Discharge air from non-combustion equipment that captures contaminants shall be exhausted to the outdoors

5.7 Combustion Air

Follow manufacturer’s instructions to provide sufficient combustion air and exhaust air for indoor fuel-fired appliances Products of combustion from vented appliances shall be vented directly outdoors

General Requirements 5. Systems and Equipment

5.8 Particulate Matter Removal

Use a filter rated at MERV 6 (or greater) upstream of cooling coils and other wet-surface devices in supply stream

General Requirements 5. Systems and Equipment

5.9 Dehumidification Systems

Must be able to limit indoor RH to 65% or less at design dew point condition

Exception to RH limit - where occupancy requirements or processes dictate higher RH conditions

Intake airflow must be greater than relief/exhaust during cooling (to minimize moist air infiltration)

General Requirements 5.9 Dehumidification Systems 65% RH limit

62°F DP

General Requirements 5. Systems and Equipment

5.10 Drain Pans

Assure drainage without flooding or carryover Slope: 0.125” (1/8”) per foot toward outlet Drain: located at lowest point, with sufficient diameter prevent overflow Drain seal: Shall include P-trap or other seal for negatively pressurized drain pans to prevent ingestion of air while allowing complete drainage (fan on or off) Pan size: length at least 1/2 coil height or as necessary to limit carryover

General Requirements 5. Systems and Equipment

5.11 Finned Tube Coils and Heat Exchangers

Provide drain pan beneath all dehumidifying cooling coil assemblies and all condensate producing heat exchangers Select to limit coil pressure drop to 0.75 [email protected] 500 fpm face velocity

Exception- higher pressure drop can be accommodated by providing access on both sides and providing clear and complete instructions for maintenance

General Requirements 5. Systems and Equipment

5.12 Humidifiers and Water Spray Systems

Use potable water (or better) No downstream devices within absorption distance

Exception- devices or obstructions provided with appropriate drain pan

General Requirements 5. Systems and Equipment

5.13 Access for Inspection, Cleaning and Maintenance.

Install equipment with sufficient working space for access and maintenance Provide access doors, panels or other means to allow convenient and unobstructed access for maintenance of the HVAC system

General Requirements 5. Systems and Equipment

5.14 Building Envelope and Interior Surfaces

Weather barrier to prevent water penetration into envelope

Vapor retarder or other means to prevent condensation on cold surfaces within envelope

Seal all exterior seams, joints, penetrations to limit infiltration

Insulate pipes and ducts expected to have surface temperature below surrounding dew point

General Requirements 5. Systems and Equipment

5.15 Buildings with Attached Parking Garages.

Limit infiltration of vehicular exhaust:

Maintain garage pressure at or below adjacent occupied space Or, use a vestibule Or, otherwise design to minimize air migration from garage to occupied space

General Requirements 5. Systems and Equipment

5.16 Air Classification and Recirculation.

Designate expected air quality classification for all return transfer or exhaust air (refer to table 5.2, 6.1 and 6.4 for examples of air classes)

Class 1: Low contaminant concentration

Class 2: Moderate concentration

Class 3: Significant concentration

Class 4: Highly objectionable or potentially harmful concentration

General Requirements 5. Systems and Equipment

Recirculation limitations

Class 1 to anywhere Class 2 to self, similar Class 2 or Class 3 or Class 4

Class 3 to self

Class 4 to outdoors

General Requirements 5. Systems and Equipment

Re-designation of air class

Air Cleaning- may allow re-designation of the air to a cleaner classification. Transfer- a mixture of air with different classes shall be re-designated with the highest class of classification among the air classes mixed. Energy Recover- energy recovery from class 2 (exhaust) airstreams must have no more than 10% leakage into a class 1 airstream.

General Requirements 5. Systems and Equipment

5.17 Requirements for buildings containing ETS areas and ETS-Free areas.

Note - Does not purport to achieve acceptable IAQ in ETS areas.

Spaces must be classified as ETS or ETSFree

ETS-Free areas shall be at a positive pressure in relation to ETS areas

General Requirements 5. Systems and Equipment

5.17 (continued)

ETS-Free areas must be kept separate by means of solid walls, floors, ceilings and doors with automatic closers. Recirculation or transfer from ETS to ETS-Free is prohibited ETS areas must be exhausted to prevent recirculation to ETS-Free areas

Ventilation Requirements 6. Procedures

6.1 General- Three different procedures are available to determine the outdoor airflow rates for mechanical ventilation systems.

Ventilation Rate Procedure- Prescribes rates & procedures based on typical space contaminant sources & source strengths

Ventilation Requirements 6. Procedures

IAQ Procedure- Requires calculation of rates based on analysis of contaminate sources, concentrations and perceived air quality targets Natural Ventilation Rate ProcedurePrescribes design criteria for ventilation air to be provided through openings to the outdoors

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.1 Outdoor Air Treatment. If outdoor air is judged to be unacceptable per Section 4.1 assessment

MERV 6 filter in PM10 non-attainment regions

MERV 11 filter in PM2.5 non-attainment regions

40% efficient ozone filter in some ozone nonattainment regions

Other – document assumptions

Air Data: PM10

Air Data: Ozone Above 160 ppb: Fresno, Riverside, Long Beach

Ventilation requirements 6.2 Ventilation Rate Procedure

6.2.2 Zone Calculations.

Use Table 6.1 rates (both cfm/person and cfm/sf) to find breathing zone outdoor airflow: Vbz = Rp*Pz + Ra*Az

GENERAL NOTES FOR TABLE 6-1

1 Related requirements: The rates in this table are based on all other applicable requirements of this standard being met. 2 Smoking: This table applies to nosmoking areas… 4 Default occupant density: The default occupant density shall be used when actual occupant density is not known.

Ventilation Rate Procedure Minimum Ventilation Rates

Table 6-1: Minimum breathing-zone rates for 78 categories Std 62-2001

Std 62.1-2010

Rp cfm/p

Ra cfm/ft²

Rp cfm/p

Ra cfm/ft²

Office

20

0.0

5.0

0.06

Classroom (ages 5-8)

15

0.0

10.0

0.12

Lecture classroom

15

0.0

7.5

0.06

Retail sales

0

0.3

7.5

0.12

Auditorium

15

0.0

5.0

0.06

Occupancy category

Prescribes both per-person and per-area rates

Ventilation Rate Procedure Minimum Ventilation Rates Comparison of breathing-zone OA flow Std 62-2001

Std 62.1-2010

Occupancy category (default density/1000 ft²)

Vbz cfm

Effective cfm/p

Vbz cfm

Office

100

20.0

85

17.0

Classroom (ages 5-8) (25p)

375

15.0

370

15.0

Lecture classroom

(65p)

975

15.0

550

8.5

Retail sales

(15p)

300

20.0

233

16.0

Auditorium

(150p)

2250

15.0

810

5.4

(5p)

Effective cfm/p

Most OA flow rates go down a little … some, a lot!

Zone Outdoor Airflow

Use Table 6.2 defaults to find zone air distribution effectiveness, Ez Find zone outdoor airflow for each zone: Voz = Vbz/Ez

Ez can range from 0.5 to 1.2 Ez=0.8 with certain common heating designs. This is 25% more OA.

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.3 Single-Zone Systems. Find system-level outdoor air intake flow: Vot = Voz

6.2.4 100% Outdoor Air Systems. Find system-level outdoor air intake flow: Vot = Σ Voz

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.5 Multiple-Zone Recirculating Systems. Use prescribed equations to find outdoor air intake flow (Vot):

[

1 × D ∑allzones R p Pz + ∑allzones Ra Az Vot = Ev

]

Spreadsheets

There is a spreadsheet supplied with the Users manual that aids in calculating Vot, the air required at the outdoor air intake.

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.6 Design for Varying Operating Conditions.

Must provide required ventilation rates whenever occupied

May (optional) base design calculations on averages over three time-constants: T = 3 ν / Vbz

(IP units)

Average zone population (Pz) when population varies

Average breathing zone outdoor airflow (Vbz) when primary airflow varies

Average outdoor air intake flow (Vot) when intake flow varies

Ventilation Requirements 6.2 Ventilation Rate Procedure

6.2.7 Dynamic Reset

May (optional) reset intake (Vot) or zone minimum airflow based on variations in estimated occupancy, efficiency, or actual intake airflow

Ventilation Requirements 6.3 IAQ Procedure

Performance-based design approach Designed to maintain the concentrations of specific contaminants and Achieve the design target level of perceived indoor air quality acceptability

Ventilation Requirements 6.3 IAQ Procedure (cont)

Allows contaminant removal through air cleaning in addition to ventilation

Allows tailoring ventilation rate to specifics of the space

May allow ventilation rates to be reduced below levels prescribed by the Ventilation Rate Procedure. IAQ Procedure requirements are being made more specific

Ventilation Requirements 6.3 IAQ Procedure

Designing for compliance using the IAQ Procedure requires four steps:

Identify contaminants of concern, along with sources and emission rates

Specify target concentration and exposure time

Specify target perceived air quality in terms of percent satisfied

Follow an acceptable design procedure to find required airflow values.

Ventilation requirements 6.3.4 IAQ Procedure

Rate is larger of that determined by

Mass balance analysis, AND

Subjective Evaluation, OR

Design approaches that have proved successful in similar buildings

Can combine VRP and IAQP

Ventilation Requirements 6.3.4.1 IAQ Procedure (cont)

Mass balance analysis equations are provided in Appendix D Equations are limited to the steady-state analysis of a single zone Not specified by the Standard, but use simulation software for multiple zone systems

Ventilation Requirements 6.3 IAQ Procedure

May be used:

To take credit for low-emitting materials

To take credit for air cleaning

To achieve specific target concentrations of one or more contaminants

To achieve specific levels of perceived IAQ (percent satisfied)

Does not apply for ETS … no acceptable concentration to reference

Ventilation Requirements 6.4 Natural Ventilation

Requires occupant controllable openings to outdoors Minimum size of openings based on floor area to be ventilated Requires mechanical ventilation system be installed – VRP or IAQP

Ventilation Requirements 6.4 Natural Ventilation

Floor area that can be naturally ventilated based on multiple of ceiling height Multiplier based on opening configuration

One-sided – 2h

Two-sided – 5h

Corner – 5h along line

Ventilation Requirements 6.5 Exhaust Ventilation

Must provide exhaust for some space types Rates prescribed in Table 6.4. For instance:

Kitchenettes

0.30 cfm/ft2

Public toilet

50 cfm/unit (typ)

Art classroom

0.70 cfm/ft2

Construction Requirements 7. Construction/Start-Up

7.1 Construction Phase

Don’t operate air handlers without filters

Protect building materials

Protect occupied areas

Limit migration of construction contamination into occupied space

Construction Requirements 7. Construction/Start-Up

Air Duct System Construction shall be in accordance with the SMACNA duct construction standards and NFPA standards governing installation of HVAC systems 7.2 System Start-Up- Defines the testing or inspecting for cleanliness, functional operation and balancing of the HVAC system

Construction Requirements 7. Construction/Start-Up

Documents shall be provided to Owner including:

Balancing report,

As-built construction drawings, and

Design criteria with assumptions

Operating Requirements 8. Operation & Maintenance

8.2 Operations and Maintenance Manual.

Develop a building operations and maintenance manual which shall include a maintenance schedule with frequencies of tasks. O&M manual shall be provided to Owner of the building

Operating Requirements 8. Operation & Maintenance

8.3 Ventilation System OperationOperate in accordance with Building O&M Manual and Section 6 when spaces are expected to be occupied. 8.4 Ventilation System MaintenanceMaintain in accordance with Building O&M Manual or as required by Section 8.

Saving Energy

Careful design

Maximize effectiveness and efficiency

Vary operation as conditions change

Use time averaging when appropriate

Saving Energy

DOAS

Separates ventilation from temperature control Allows optimizing ventilation

Natural ventilation

Must control mechanical system properly!

Saving Energy

IAQ Procedure

Most appropriate for multiple similar buildings

Known contaminants that can be cleaned

Designer/Owner must accept liability

Not LEED!

SSPC 62.1

Standard is under continuous maintenance

Anyone can propose a change to the standard

Notice of proposed changes appears in ASHRAE Standards Action

Anyone can comment on proposed changes

Anyone can request an interpretation

ASHRAE Standard 62.1-2010 & Related Activities…

Std 62.1-2010 is the current version IMC & UMC adopted equations and ventilation rates Several educational courses are available from ASHRAE

ASHRAE 62.1 Resources

User’s Manual for 62.1-2010

IMC & UMC Code adoption

ALI Short Course and Professional Development Course

eLearning course

IAQ Design Guideline is published

Next publication – ASHRAE 62.1-2013

ASHRAE 62.1 Future Changes

Complete ventilation shutoff when zero occupancy

More specifics for multizone DCV

More refinement for space types

Better integration for VRP and Exhaust

More space types?

ASHRAE 62.1 Future Changes

IAQP

More design guidance

More rigor

Code/LEED acceptance?

General improvements

Code integration

Questions? Roger Hedrick [email protected] 303 459 7481

- Available Formats

- Options

- Availability

- Priced From ( in USD )

- 👥

- Immediate download

- $166.00

- Printed Edition

-

- Ships in 1-2 business days

- $166.00

- Printed Edition + PDF

-

- Immediate download

- $241.00

Customers Who Bought This Also Bought

ASHRAE 114-1986

Priced From $34.00ASHRAE 198-2013

Priced From $66.00ASHRAE 195-2013

Priced From $66.00ASHRAE 133-2015

Priced From $53.00

About This Item

Download ashrae heat load calculation excel sheet xls hvac spreadsheet t calculator for everyone heating and cooling. Windows 10 update 1607 manual download pdf. Manual j load calculation form best of residential heat ashrae spreadsheet n. Heating and cooling load calculators hvac heat calculation spreadsheet. White Papers, ASHRAE Datacom Series. The ASHRAE Datacom Series includes 13 publications which provide a comprehensive treatment of datacom cooling and related subjects. TC 9.9 published documents to expand the recommended environmental envelope. Click on the following links to learn more about the free supplemental downloads available. . Mariner service manual. User’s Manual – First published in 2005, updated in 2007, 2010, and 2013, next scheduled update 2016. – Provides information on how to use and apply Standard 62.1 with practical examples of compliance. Advanced IAQ Design Guide – Best practices for design, construction & commissioning. ASHRAE Standard 62.1-2013.

Full Description

Full Description

New! Get more out of ASHRAE Standard 90.1 with a new online portal.

Once purchased, users can personalize their experience to access up-to-date Standard 90.1 resources in one consolidated location. Features of the portal include:

Standard 90.1 has been a benchmark for commercial building energy codes in the United States and a key basis for codes and standards around the world for more than 35 years. This standard provides the minimum requirements for energy-efficient design of most buildings, except low-rise residential buildings. It offers, in detail, the minimum energy efficiency requirements for design and construction of new buildings and their systems, new portions of buildings and their systems, and new systems and equipment in existing buildings, as well as criteria for determining compliance with these requirements. It is an indispensable reference for engineers and other professionals involved in design of buildings and building systems.

The 2019 edition includes various modifications and clarifications to improve internal consistency and to standardize the structure and language of the document.

Significant changes to requirements include the following

Administration and Enforcement

Building Envelope

- Combined categories of “nonmetal framed” and “metal framed” products for vertical fenestration

- Upgraded minimum criteria for SHGC and U-factor across all climate zones

- Revised air leakage section to clarify compliance

- Refined exceptions related to vestibules, added new option and associated criteria for using air curtains

Lighting

- Modified lighting power allowances for Space-by-Space Method and the Building Area Method

- New simplified method for lighting for contractors and designers of renovated office buildings and retail buildings up to 25,000 ft2 (2300 m2).

- Updated lighting control requirements for parking garages to account for the use of LEDs

- Updated daylight responsive requirements, added definition for “continuous dimming” based on NEMA LSD-64-2014

- Clarified side-lighting requirements and associated exceptions

Mechanical

- New requirements to allow the option of using ASHRAE Standard 90.4 instead of ASHRAE Standard 90.1 in computer rooms that have an IT equipment load larger than 10 kW

- Added pump definitions, requirements, and efficiency tables to the standard for the first time

- New equipment efficiency requirement tables and changes to existing tables

- Replaced fan efficiency grade (FEG) efficiency metric with fan energy index (FEI)

- New requirements for reporting fan power for ceiling fans and updated requirements for fan motor selections to increase design options for load-matching variable-speed fan applications

- New energy recovery requirements for high-rise residential building

- New requirement for condenser heat recovery for acute care inpatient hospitals

Energy Cost Budget (ECB) Method (Section 11)

- Numerous changes to ensure continuity

- Set baseline for on-site electricity generation systems

Performance Rating Method (Appendix G)

- Clarified Appendix G rules and corresponding baseline efficiency requirement when combining multiple thermal zones into a single thermal block

- New explicit heating and cooling COPs without fan for baseline packaged cooling equipment

- New rules for modeling impact of automatic receptacle controls

- Set more specific baseline rules for infiltration modeling

- Clarified how plant and coil sizing should be performed

- Updated building performance factors

Both Compliance Paths

- Clearer, more specific rules for treatment of renewables

- New updates to rules for lighting modeling

Document History

Amendments, rulings, supplements, and errata

Ashrae Manual J Pdf

Browse related products from ASHRAE

- ASHRAE >Standards and Guidelines >Current Standards